Engine Antifreeze Coolant: Practical Selection Rules for Stable Cooling and Lower Maintenance Cost

In industrial and commercial engines, engine antifreeze coolant is not a background consumable.

It is a working fluid that continuously affects heat transfer efficiency, material aging, and maintenance frequency.

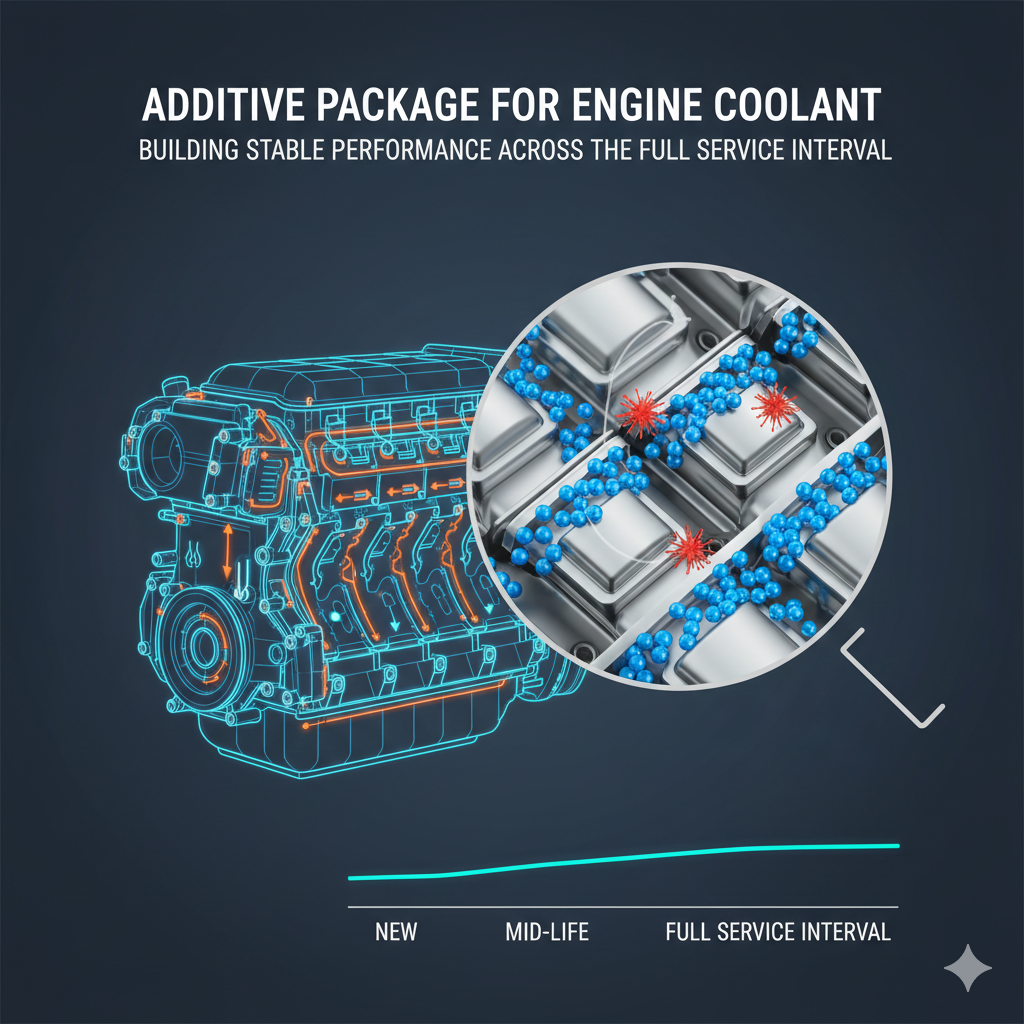

Most cooling system failures are not caused by sudden breakdowns. They are the result of long-term coolant instability—corrosion inhibitors depleting unevenly, deposits forming on heat-transfer surfaces, and chemical imbalance accelerating component wear. These problems are rarely visible early, but costly once they surface.

This article focuses on practical selection rules that engineers and buyers can use to reduce cooling system risk and control maintenance cost over time.

What Stable Engine Cooling Requires in Real Operation

For a cooling system to remain reliable, antifreeze coolant must deliver four outcomes at the same time:

-

Consistent heat transfer under load

-

Long-term corrosion protection across mixed metals

-

Chemical stability over extended service intervals

-

Minimal side effects such as deposits or electrical sensitivity

If one of these fails, the system usually compensates with more frequent maintenance rather than immediate failure—masking the real cause.

Coolant Formulation Decisions That Actually Matter

Engine antifreeze coolant performance is defined by formulation, not by freezing point alone.

A stable coolant system combines:

-

A suitable base fluid for thermal capacity

-

A corrosion inhibitor package matched to engine materials

-

Buffer systems that keep pH stable over time

-

Additives that prevent foaming and surface deposits

Among these, the inhibitor package determines long-term behavior. Engines using aluminum housings, copper radiators, and steel components require balanced inhibitor chemistry. Generic formulations often protect one material while accelerating degradation in another.

Matching Coolant to Duty Cycle, Not Just Engine Type

Selecting coolant based only on engine category is a common mistake.

Engines operating with long run times, high thermal load, or limited cool-down periods stress coolant chemistry far more aggressively than intermittent-use systems.

| Operating Condition | Coolant Selection Focus |

|---|---|

| Intermittent, light load | Standard antifreeze coolant |

| Continuous operation | Heavy duty engine coolant |

| High localized temperature | Enhanced inhibitor reserve |

| Extended service interval | Long-life formulation |

Correct matching at this stage significantly reduces corrosion-related maintenance later.

Maintenance Cost Is Driven by Coolant Stability, Not Replacement Frequency

Replacing coolant more often does not fix instability.

It only delays visible symptoms.

In unstable formulations, inhibitors deplete unevenly, pH drifts near hot zones, and deposits gradually reduce heat transfer efficiency. Stable formulations, by contrast, maintain protective balance throughout the service interval.

| Cost Indicator (Typical Industrial Engine) | Low-Stability Coolant | Stable, Matched Coolant |

|---|---|---|

| Replacement interval | 12–18 months | 36–60 months |

| Maintenance interventions (per year) | 2–3 | 0–1 |

| Heat transfer efficiency loss (12 months) | 5–8% | <2% |

| Corrosion-related component replacement | Every 2–3 years | >5 years |

| Cooling-related maintenance cost (5 years) | 100% (baseline) | 60–70% |

Over time, coolant stability has a larger impact on total cost than replacement frequency.

Practical Coolant Selection Checklist for Engineers and Buyers

Beyond defining operating temperature and freeze protection, effective coolant selection should reduce long-term uncertainty.

In practice, this means:

-

Understanding material compatibility, not just datasheet values

-

Selecting formulations designed for the actual duty cycle

-

Ensuring technical support is available when conditions change

FYeco supports this process by combining antifreeze base fluids with application-specific additive packages. This allows coolant solutions to be matched to continuous operation, mixed-metal systems, or electrically sensitive environments without relying on trial-and-error replacement cycles.

Q&A

Q: Can one antifreeze coolant cover different engine models?

A: Only if duty cycle, materials, and service expectations are similar. Otherwise, formulation mismatch risk increases.

Q: Is heavy duty engine coolant always the better choice?

A: No. It is designed for specific operating conditions and may be unnecessary for light-duty applications.

Q: What matters more, price or formulation stability?

A: Formulation stability. Long-term maintenance cost differences usually outweigh initial price differences.

Turning Coolant Selection into a Reliability Advantage

Engine antifreeze coolant should be treated as part of the engine system, not as an interchangeable consumable.

FYeco focuses on antifreeze coolants and additive solutions designed around real operating conditions, including continuous duty cycles, mixed-metal systems, and applications with higher stability requirements. By reviewing suitable coolant options within FYeco’s product portfolio, engineers and buyers can better match formulation performance to actual operating needs, rather than relying on generic specifications.

👉 View available coolant and additive solutions: https://www.fyecosolution.com/products

For projects with higher thermal load, extended service intervals, or tighter reliability targets, discussing system details directly with the FYeco team helps ensure coolant selection follows a clear and practical process—from requirement analysis to formulation matching and ongoing technical support. If you are evaluating options or facing specific cooling challenges, you can reach out through the contact page to start a technical discussion.

👉 Contact FYeco for application support: https://www.fyecosolution.com/contact-us