Heavy Duty Engine Coolant vs Standard Coolant: Real Cost and Maintenance Differences

In industrial and commercial engines, coolant selection is often simplified to a binary choice: standard or heavy duty.

In practice, this decision has a direct impact on maintenance frequency, component lifespan, and long-term operating cost.

The difference between these two coolant types is not marketing language. It is rooted in formulation design, inhibitor reserve, and long-term chemical stability under real operating conditions.

This article focuses on what actually changes in operation when heavy duty engine coolant replaces standard coolant—and when it does not.

Where Standard Coolant Reaches Its Limits

Standard engine coolant is typically formulated for intermittent operation and moderate thermal stress.

In such environments, it performs reliably and economically.

Problems begin when operating conditions shift toward:

-

Long continuous run time

-

High localized temperatures

-

Limited cool-down cycles

-

Extended service intervals

Under these conditions, standard coolant often shows early signs of instability. Corrosion inhibitors deplete faster, pH control weakens near hot zones, and deposits begin forming on heat-transfer surfaces. These changes rarely cause immediate failure, but they steadily increase maintenance workload.

What Makes Heavy Duty Engine Coolant Behave Differently

Heavy duty engine coolant is not simply “more concentrated” coolant.

Its formulation is designed to remain chemically stable over longer service periods.

Key differences usually include:

-

Higher inhibitor reserve to sustain protection over time

-

Improved pH buffering under thermal stress

-

Better mixed-metal corrosion control

-

Lower tendency to form deposits under high heat

This allows heavy duty coolant to tolerate harsher operating conditions without relying on frequent replacement to maintain performance.

Maintenance Impact Comparison in Real Operation

The practical difference between these two coolant types becomes clear over time, not at installation.

| Performance Indicator | Standard Coolant | Heavy Duty Engine Coolant |

|---|---|---|

| Typical service interval | 12–18 months | 36–60 months |

| Inhibitor depletion rate | Fast under load | Controlled |

| Heat transfer efficiency loss (12 months) | 5–8% | <2% |

| Corrosion-related component replacement | Every 2–3 years | >5 years |

| Cooling-related maintenance events | Frequent | Occasional |

For engines operating continuously, these differences directly affect downtime risk and maintenance planning.

Cost Comparison: Purchase Price vs Lifecycle Cost

At the purchasing stage, heavy duty engine coolant usually costs more per unit.

However, purchase price represents only a small fraction of total cooling system cost.

| Cost Element (5-Year Operation) | Standard Coolant | Heavy Duty Coolant |

|---|---|---|

| Coolant purchase cost | Lower | Higher |

| Labor and downtime | Higher | Lower |

| Component replacement | Frequent | Reduced |

| System flushing frequency | High | Low |

| Total cooling-related cost | 100% (baseline) | 60–75% |

For engines with high utilization, lifecycle cost consistently favors heavy duty formulations despite higher upfront pricing.

When Heavy Duty Engine Coolant Is Necessary — And When It Is Not

Heavy duty engine coolant is not automatically the better choice for every application.

It is recommended when:

-

Engines run continuously or near full load

-

Thermal stress is high or uneven

-

Long service intervals are required

-

Mixed-metal systems show corrosion sensitivity

Standard coolant remains appropriate when:

-

Operation is intermittent

-

Thermal load is moderate

-

Service intervals are short and predictable

Matching coolant type to actual operating conditions prevents over-specification as well as underperformance.

How Formulation Support Reduces Selection Risk

One of the main risks in coolant selection is relying solely on generic product categories.

In practice, engines with similar power ratings can have very different cooling demands due to material combinations, duty cycles, and electrical sensitivity. This is why formulation-level support matters more than choosing between “standard” and “heavy duty” labels.

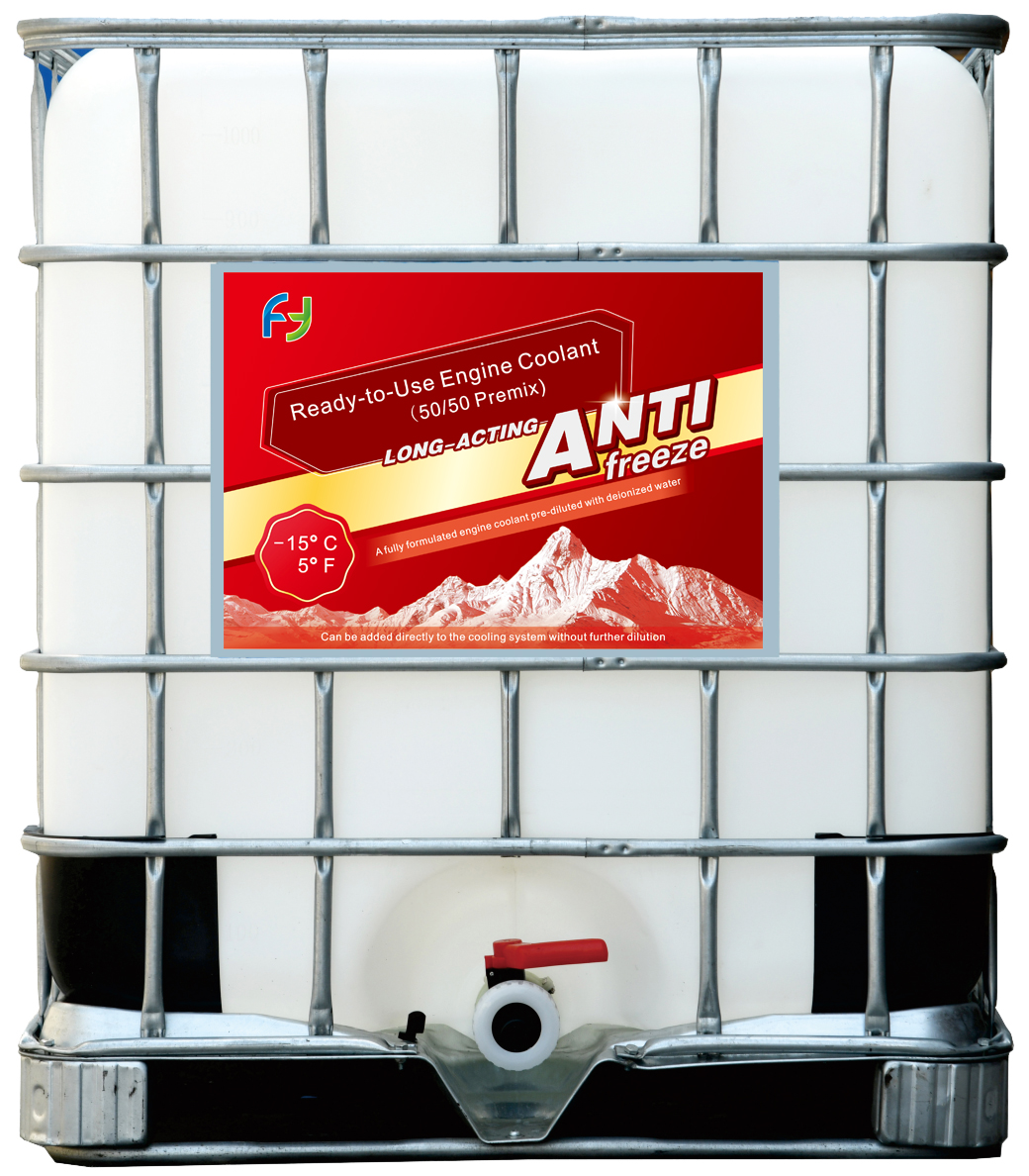

FYeco addresses this by offering antifreeze coolants and additive packages designed around application conditions, allowing coolant performance to be aligned with real system behavior rather than assumptions.

Q&A

Q: Can heavy duty coolant be used in all engines?

A: It can, but it may be unnecessary for light-duty or intermittent applications and may increase cost without added benefit.

Q: Does heavy duty coolant always extend service interval?

A: Only when operating conditions justify it. Stability depends on formulation matching, not product name alone.

Q: Is switching to heavy duty coolant a fix for existing corrosion issues?

A: It can slow further degradation, but existing damage should be addressed separately before conversion.

Making the Right Coolant Choice for Long-Term Stability

Choosing between heavy duty engine coolant and standard coolant should be based on operating reality, not habit or initial cost.

For industrial engines facing higher thermal load or extended service expectations, reviewing suitable coolant options helps reduce maintenance risk and improve system stability. You can explore available antifreeze coolants and additive solutions through FYeco’s product portfolio at

https://www.fyecosolution.com/products

If your application involves continuous operation, mixed-metal systems, or recurring cooling issues, discussing system details directly with the FYeco team allows coolant selection to follow a clear, application-driven process. You can start that conversation through the contact page at

https://www.fyecosolution.com/contact-us