Concentrated Antifreeze Supplier: What Automotive Buyers Should Evaluate Beyond Price

In automotive engine programs, concentrated antifreeze is not chosen for convenience—it is chosen for control. Vehicle manufacturers, aftermarket brands, and fleet operators continue to specify concentrated coolant because it allows flexibility in formulation, storage, and regional adaptation.

However, once dilution responsibility shifts from the factory to the buyer or service network, the reliability of the concentrated antifreeze supplier becomes a decisive factor. Inconsistent base fluid quality, unstable additive systems, or unclear technical support can quickly translate into field issues that appear months later inside the engine.

Understanding what truly differentiates a qualified supplier requires looking at formulation behavior, not just product specifications.

Why Automotive Programs Still Use Concentrated Antifreeze

In automotive applications, concentrated antifreeze serves several practical purposes that ready-mix solutions cannot fully replace.

First, it allows concentration adjustment to match climate requirements across regions. Second, it improves logistics efficiency by reducing transportation volume and storage space. Third, it gives OEMs and aftermarket brands greater control over how coolant is integrated into existing service processes.

For automotive engines with varied duty cycles and global distribution, these advantages outweigh the added responsibility of correct dilution—provided the concentrate itself is consistent and chemically stable.

What “Concentrated” Really Means in Automotive Cooling Systems

In automotive engine cooling, concentrated antifreeze is not simply a stronger version of ready-mix coolant. It is a chemical base designed to be diluted with controlled water quality to achieve target performance.

This means the concentrate must:

-

Maintain additive stability before and after dilution

-

Deliver predictable viscosity and flow once mixed

-

Preserve corrosion protection across aluminum and mixed-metal engines

A supplier’s formulation design determines whether these conditions hold true in real service environments.

Key Technical Differences Among Concentrated Antifreeze Suppliers

Not all concentrates behave the same once diluted and introduced into automotive engines.

| Technical Factor | Reliable Supplier | Inconsistent Supplier |

|---|---|---|

| Base fluid purity | Controlled, traceable | Variable, batch-dependent |

| Additive solubility | Stable after dilution | Risk of separation or dropout |

| pH control range | Predictable after mixing | Drifts under heat cycling |

| Compatibility with aluminum engines | Validated | Assumed, not tested |

| Dilution tolerance | Clearly defined | Narrow or undocumented |

These differences explain why some cooling systems experience early degradation even when dilution ratios appear correct.

How Concentrated Antifreeze Performs in Real Driving Conditions

Once diluted and filled into an automotive engine, concentrated antifreeze undergoes the same stresses as any coolant—but with an added variable: field preparation quality.

Urban driving introduces frequent heat cycling, while highway operation accelerates oxidation. Seasonal changes repeatedly test freeze and boil protection margins. If additive balance is not robust, inhibitors deplete unevenly, and deposits may form on heat-transfer surfaces.

A well-formulated concentrate maintains chemical balance across these conditions, while weaker formulations reveal issues gradually, often after warranty periods end.

Selecting a Concentrated Antifreeze Supplier for Automotive Use

Choosing a supplier is less about catalog specifications and more about process reliability.

Automotive buyers should evaluate:

-

Whether formulation consistency is maintained across production batches

-

How dilution guidelines are validated under real engine conditions

-

Whether compatibility testing covers modern aluminum engine designs

-

If technical support can address platform-specific cooling challenges

A supplier that supports only product delivery but not application guidance often leaves buyers exposed to long-term risk.

Cost Control and Supply Chain Considerations

From a procurement perspective, concentrated antifreeze offers advantages in transportation efficiency and inventory management. However, these savings disappear quickly if dilution errors or formulation instability lead to increased maintenance or engine issues.

Reliable suppliers mitigate this risk by providing clear dilution parameters, stable formulations, and application-level guidance—reducing total lifecycle cost rather than focusing on unit price alone.

Q&A

Q: Is concentrated antifreeze more prone to errors than ready mix?

Only if dilution control and supplier guidance are insufficient.

Q: Can one concentrate be used across multiple vehicle platforms?

Sometimes, but compatibility with engine materials must be verified.

Q: Does concentrate extend coolant service life?

Service life depends on formulation stability, not concentration form.

Working with a Qualified Concentrated Antifreeze Supplier

In automotive engines, concentrated antifreeze delivers flexibility and efficiency when supported by robust formulation design and technical consistency.

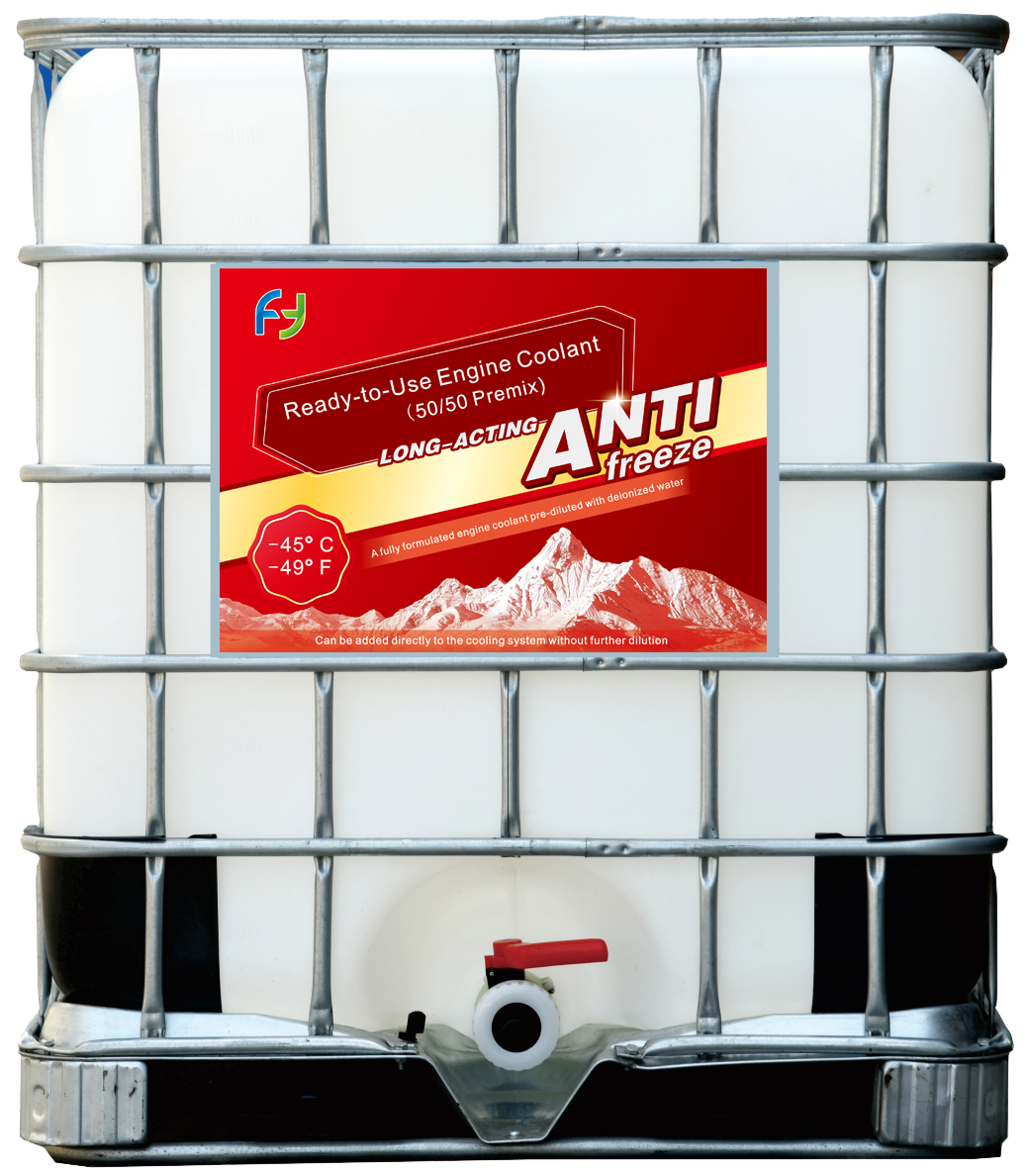

FYeco supplies automotive antifreeze concentrates developed for stable dilution behavior and long-term cooling system reliability. Reviewing available solutions within FYeco’s product portfolio allows buyers to assess whether concentrated antifreeze fits their vehicle platforms and service models.

https://www.fyecosolution.com/products

For automotive programs or aftermarket brands managing diverse climates and service conditions, discussing dilution practices and engine requirements with the FYeco team helps ensure coolant selection is driven by real application needs rather than assumptions.

https://www.fyecosolution.com/contact-us