Long Life Antifreeze Coolant: How Extended Service Life Is Achieved in Real Engine Systems

In real automotive and industrial engine systems, extended coolant service life is not achieved by specification labels or advertised drain intervals. It is achieved when chemical stability, additive consumption rate, and operating conditions remain aligned over time.

Many cooling system issues appear not because a coolant performs poorly at the beginning, but because its formulation cannot maintain balance as temperature, load, and exposure accumulate. Understanding how long-term stability is built—and where it fails—is essential when evaluating long service solutions.

Formulation Design That Supports Extended Service Life

Extended service performance begins at the formulation level rather than at the replacement schedule.

Long life antifreeze coolant is engineered to maintain predictable chemical behavior over prolonged operation, instead of delivering peak protection only at the early stage of use. This is achieved through a combination of controlled inhibitor activity, buffering strategy, and additive compatibility.

Key formulation principles include:

-

Corrosion inhibitors designed to react gradually with metal surfaces, forming protective films without rapid depletion

-

Buffer systems sized to absorb slow chemical drift caused by heat, oxygen ingress, and minor contamination

-

Additive packages formulated to minimize secondary reactions that lead to deposits or loss of heat transfer efficiency

When any of these elements is unbalanced, service life shortens regardless of initial laboratory performance.

Material and Additive Architecture Behind Long-Term Stability

From a product perspective, long service performance depends more on additive architecture than on base fluid selection alone.

A stable extended-life formulation typically consists of:

-

A base fluid chosen for thermal consistency and viscosity control over time

-

A corrosion inhibition system optimized for slow, even consumption

-

Buffer components capable of maintaining pH stability under continuous exposure

-

Compatibility additives protecting seals, elastomers, and mixed-metal components

Two coolants with similar base fluids can behave very differently over time if their additive systems are designed for different service expectations.

Operating Conditions That Influence Real-World Service Life

Service life is not a fixed property of the coolant itself; it is the outcome of how the coolant interacts with the engine system.

| Operating Condition | Influence on Long-Term Stability |

|---|---|

| Continuous high thermal load | Accelerates additive depletion |

| Frequent start-stop cycles | Increases chemical stress |

| Mixed-metal engine architecture | Requires balanced corrosion protection |

| Contaminant ingress | Reduces effective service window |

| Electrical sensitivity | Limits allowable conductivity range |

Ignoring these factors during selection is one of the most common reasons extended service targets fail in practice.

Selecting Coolant Based on Vehicle Type and Application Use

Extended service formulations must be matched to how the vehicle or engine is actually used, not only to nominal engine size or coolant volume.

-

Passenger vehicles

Typically operate within controlled temperature ranges and predictable duty cycles. Coolant selection focuses on long-term corrosion protection and compatibility with aluminum-dominant systems. -

Commercial and fleet vehicles

Often run for extended hours under variable load. Selection priorities include inhibitor reserve, thermal stability, and resistance to degradation during continuous operation. -

Heavy-duty and off-road vehicles

Face uneven cooling, higher contamination exposure, and limited maintenance windows. Stability under stress and deposit control become more critical than nominal drain intervals. -

Electrified and sensor-intensive vehicles

Require careful control of conductivity and material compatibility, as traditional formulations may interfere with electronic components.

Long life antifreeze coolant delivers value only when its formulation strategy aligns with vehicle category and operating profile.

Extended Service Formulations vs Standard Coolants Over Time

| Performance Aspect | Standard Coolant | Extended Service Formulation |

|---|---|---|

| Inhibitor depletion pattern | Rapid | Gradual |

| pH stability duration | Short-term | Long-term |

| Deposit formation tendency | Moderate | Lower |

| Maintenance planning | Reactive | Predictable |

| Suitability for long intervals | Limited | Designed |

The practical advantage lies in predictability and reduced intervention, not in eliminating maintenance altogether.

Q&A

Q: Does higher antifreeze concentration extend service life?

A: No. Concentration affects freeze protection, not long-term chemical stability.

Q: Can extended service formulations be used in all vehicles?

A: Only when formulation design matches vehicle materials and operating behavior.

Q: Does longer service life remove the need for monitoring?

A: No. Longer intervals require more disciplined monitoring, not less.

Applying Extended Service Solutions in Real Engine Systems

Extended service performance is achieved only when formulation stability matches real operating conditions and usage patterns.

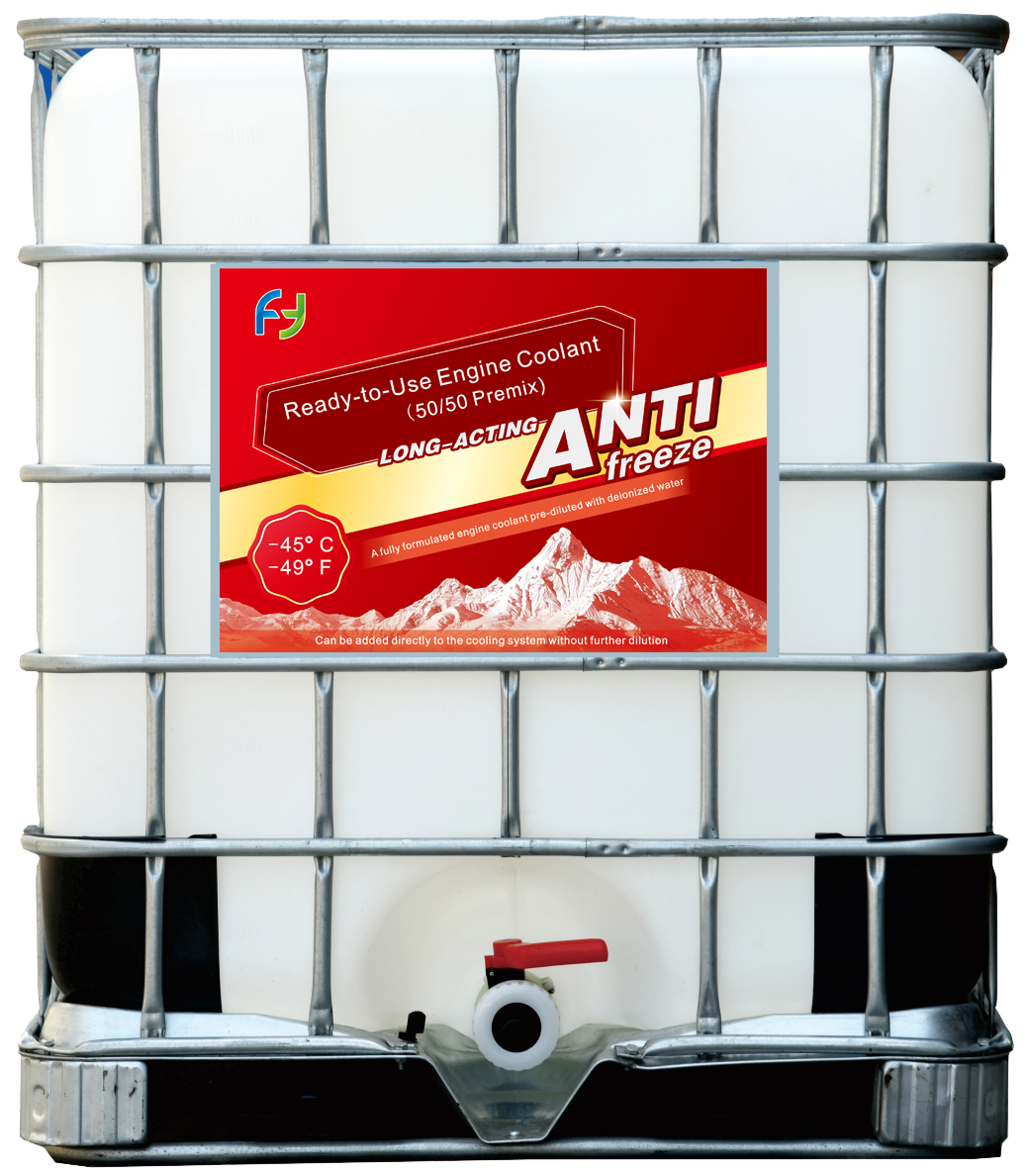

FYeco develops antifreeze and additive solutions designed for predictable performance in defined engine environments. Reviewing suitable options within FYeco’s product range allows engineers and buyers to evaluate whether long service expectations are realistic for their applications.

For projects involving continuous operation, mixed-metal systems, or strict maintenance targets, discussing application details with the FYeco team helps ensure coolant selection follows a clear, application-driven process rather than trial and error.

https://www.fyecosolution.com/products

https://www.fyecosolution.com/contact-us