Low Temperature Antifreeze -45°C: Ensuring Cold-Start Protection in Automotive Engines

In extremely cold regions, automotive engine reliability is determined long before the engine reaches normal operating temperature. Cold starts, short trips, and prolonged parking at subzero temperatures place unique demands on engine coolant performance.

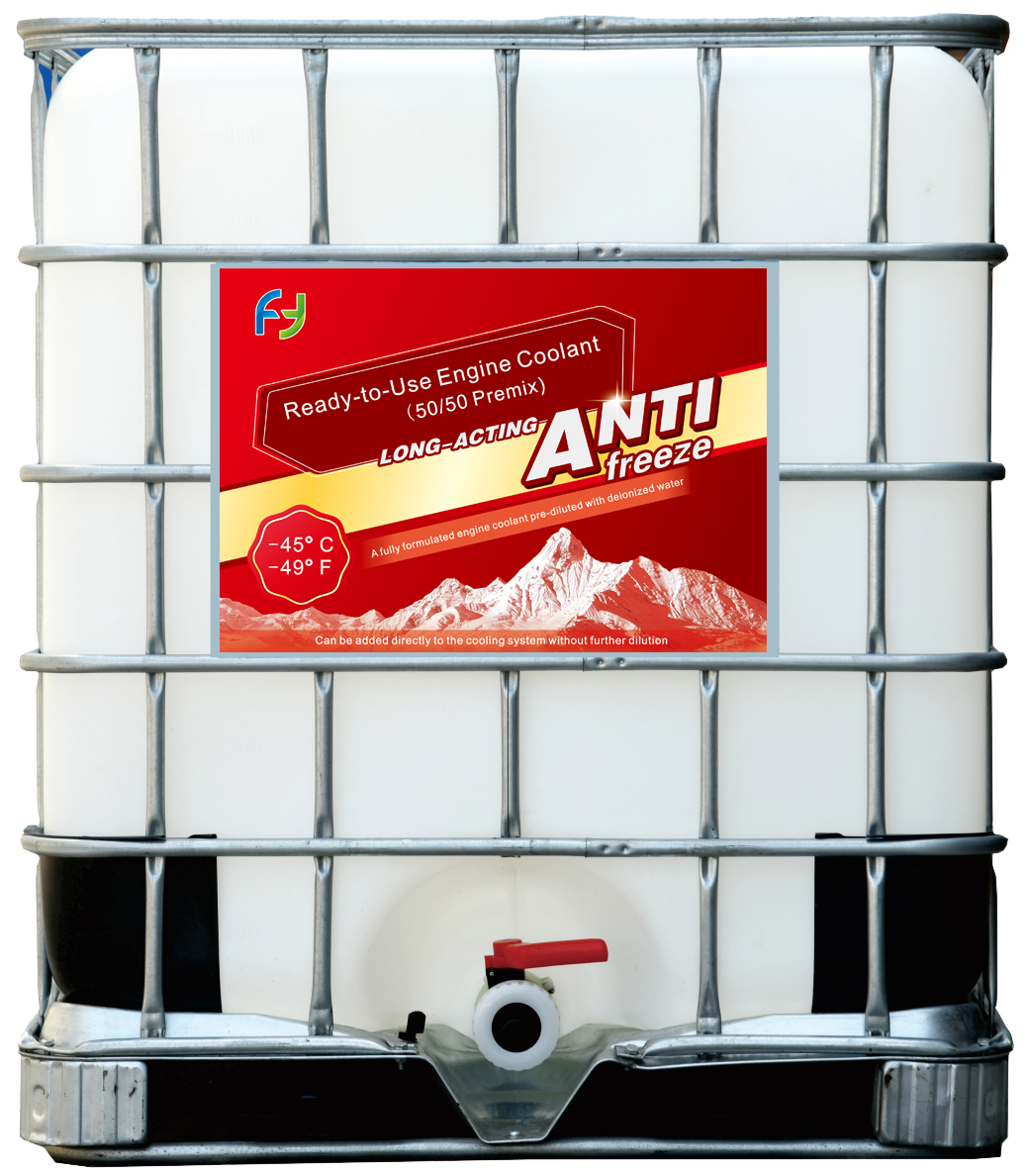

Low temperature antifreeze -45°C is designed specifically for these conditions, where standard coolant formulations may struggle with flow resistance, uneven heat distribution, or delayed circulation during startup. Understanding how this type of coolant behaves inside a car engine requires focusing on fluid dynamics and chemical stability at very low temperatures, not just freeze-point numbers.

Why –45°C Protection Matters in Real Automotive Use

The significance of –45°C antifreeze protection goes beyond preventing solidification.

At very low temperatures:

-

Coolant viscosity increases sharply, affecting pump efficiency

-

Initial circulation becomes uneven, delaying heat transfer

-

Localized cold spots increase mechanical stress on engine components

In vehicles exposed to overnight outdoor parking or long idle periods, coolant must remain fluid enough to circulate immediately after startup. Low temperature antifreeze -45°C formulations are engineered to maintain acceptable flow characteristics while preserving corrosion protection under these conditions.

Formulation Challenges in Extreme Cold Environments

Achieving stable performance at –45°C requires more than increasing glycol concentration.

As temperature drops, antifreeze formulations must balance:

-

Freeze-point depression

-

Low-temperature viscosity control

-

Additive solubility and inhibitor availability

Excessively high glycol concentration can reduce heat transfer efficiency once the engine warms up, while insufficient additive stability may lead to uneven corrosion protection. Well-designed low temperature antifreeze -45°C formulations address this by optimizing base fluid ratios and selecting additives that remain effective across wide temperature ranges.

Cold-Start Behavior Inside Automotive Engines

Cold starts are the most demanding phase for engine coolant.

When the engine is started at very low temperatures, coolant must:

-

Circulate immediately through narrow passages

-

Reach critical areas such as cylinder heads and heater cores

-

Avoid localized freezing or stagnation

Inadequate low-temperature performance can lead to delayed cabin heating, increased engine wear, and long-term stress on cooling components. Low temperature antifreeze -45°C helps mitigate these risks by maintaining fluidity and consistent inhibitor distribution during the first minutes of operation.

Selecting –45°C Antifreeze Based on Vehicle Use

Not every vehicle requires extreme low-temperature protection, but for those that do, selection should be application-driven.

Passenger Cars in Severe Winter Regions

Vehicles operated in northern climates or mountainous areas benefit from enhanced cold-start reliability, particularly during overnight exposure.

Fleet Vehicles with Outdoor Parking

Consistent cold-start performance reduces downtime and mechanical stress, especially for vehicles that must operate on fixed schedules.

Short-Trip and Stop-and-Go Driving

Frequent cold starts place repeated stress on coolant chemistry, making stable low-temperature behavior critical.

In these scenarios, low temperature antifreeze -45°C supports both mechanical reliability and driver comfort.

Performance Comparison at Extreme Low Temperatures

| Technical Aspect | –45°C Low Temperature Antifreeze | Standard Automotive Antifreeze |

|---|---|---|

| Freeze protection margin | Extended | Limited |

| Low-temperature viscosity | Optimized for flow | Higher resistance |

| Cold-start circulation | Faster stabilization | Slower |

| Additive effectiveness | Maintained | Reduced |

| Risk of localized freezing | Lower | Higher |

This comparison highlights why extreme cold protection is a system-level requirement rather than a simple numeric specification.

Procurement Considerations for Cold-Climate Vehicles

From a procurement perspective, selecting low temperature antifreeze -45°C involves evaluating formulation robustness rather than just freeze-point claims.

Key considerations include:

-

Verified low-temperature viscosity performance

-

Additive stability under repeated cold-start cycles

-

Compatibility with aluminum engine components

-

Consistency across supply batches

These factors directly affect long-term engine reliability in cold climates.

Q&A

Q: Does –45°C antifreeze improve engine warm-up speed?

It improves early circulation, which supports more stable warm-up behavior.

Q: Is –45°C antifreeze necessary for all winter regions?

No. It is most relevant where ambient temperatures regularly approach extreme lows.

Q: Can –45°C antifreeze be mixed with standard coolant?

Mixing may compromise performance unless compatibility is confirmed.

Applying Low Temperature Antifreeze in Automotive Engines

In severe winter environments, engine reliability depends on coolant behavior during the coldest moments of operation.

FYeco develops automotive antifreeze solutions designed to maintain stable flow and chemical protection in extreme low-temperature conditions, including formulations rated to –45°C. Reviewing suitable options within FYeco’s product portfolio allows engineers and buyers to determine whether enhanced cold-weather protection is appropriate for their vehicle applications.

https://www.fyecosolution.com/products

For vehicles operating in harsh winter climates or exposed to frequent cold starts, discussing operating conditions with the FYeco team helps ensure antifreeze selection aligns with real-world use rather than generic specifications.

https://www.fyecosolution.com/contact-us