Ready Mix Antifreeze Coolant: How Pre-Diluted Coolant Improves Consistency in Automotive Engines

In automotive engine cooling systems, many performance issues do not originate from coolant chemistry itself, but from how the coolant is prepared and introduced into the system. Incorrect dilution ratios, inconsistent water quality, and field-level handling errors are common causes of unstable cooling behavior.

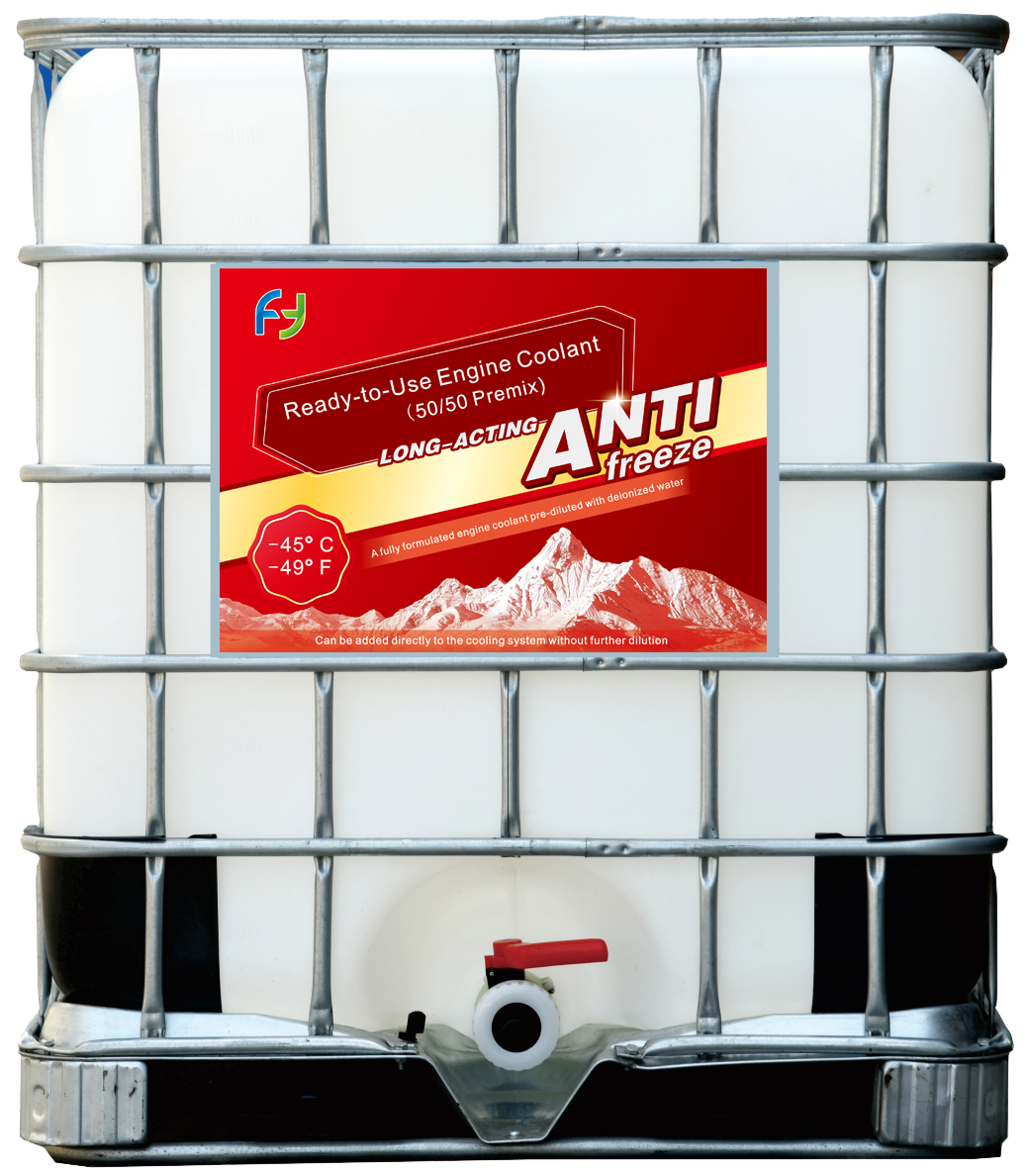

Ready mix antifreeze coolant addresses these risks by delivering a pre-diluted formulation designed to be used directly in the vehicle. In real automotive applications, this approach improves consistency across service events and reduces the variables that often compromise cooling system reliability.

Understanding when ready mix solutions make sense requires examining how dilution affects real engine behavior rather than focusing on packaging convenience alone.

Why Dilution Accuracy Matters in Automotive Engines

Automotive cooling systems are engineered around specific coolant concentrations. Deviation from the intended ratio alters not only freeze and boil protection, but also corrosion inhibition, heat transfer, and flow characteristics.

In workshop environments, dilution errors occur more frequently than expected:

-

Tap water mineral content varies by region

-

Manual mixing ratios are often estimated rather than measured

-

Partial top-ups gradually shift concentration over time

These deviations may not cause immediate failure, but they change inhibitor effectiveness and thermal stability, especially in aluminum engine blocks and modern mixed-metal systems.

Ready mix antifreeze coolant removes dilution variability by delivering a controlled, factory-prepared composition.

How Ready Mix Coolant Behaves in Real Driving Conditions

Once introduced into an automotive engine, pre-diluted coolant behaves predictably across common driving profiles.

During city driving, frequent heat cycling places stress on inhibitors and buffers. On highways, sustained load challenges thermal stability. Seasonal temperature changes repeatedly test viscosity and freeze protection margins.

Because ready mix formulations are prepared using controlled water quality and precise ratios, chemical balance remains closer to design targets throughout these cycles. This stability reduces the gradual drift that often occurs when concentrate coolant is repeatedly topped up with inconsistent water sources.

Ready Mix vs Concentrate Coolant in Automotive Use

| Technical Aspect | Ready Mix Coolant | Concentrate Coolant |

|---|---|---|

| Dilution accuracy | Fixed at factory | Dependent on service quality |

| Water quality control | Consistent, demineralized | Variable, location-dependent |

| Risk of inhibitor imbalance | Lower | Higher over multiple top-ups |

| Workshop handling | Direct fill, minimal steps | Requires accurate mixing |

| Flexibility of concentration | Limited | Adjustable |

This comparison shows that ready mix antifreeze coolant is not about higher performance on paper, but about reducing human and environmental variables that affect real-world results.

Selecting Ready Mix Coolant Based on Vehicle Use

The decision to use pre-diluted coolant should be driven by how the vehicle is serviced and operated.

Passenger Cars

For privately owned vehicles or dealership-serviced cars, ready mix coolant reduces variability between service intervals and ensures consistent protection across different locations.

Fleet Vehicles

Fleets benefit from standardized coolant use, especially when maintenance is performed by multiple technicians or at different sites. Consistency becomes more valuable than concentration flexibility.

High-Temperature or Turbocharged Engines

Stable inhibitor concentration and predictable flow behavior help maintain thermal margins, particularly where localized overheating risks exist.

In these scenarios, ready mix antifreeze coolant supports system stability rather than raw thermal efficiency gains.

Material Compatibility and System Stability

Modern automotive engines rely heavily on aluminum alloys, elastomer seals, and composite components. Coolant chemistry must protect all of these simultaneously.

Pre-diluted formulations are engineered to maintain pH balance and inhibitor availability across these materials. By avoiding field dilution errors, ready mix coolant helps prevent:

-

Localized corrosion in aluminum passages

-

Scale formation from mineral-rich water

-

Seal degradation caused by chemical imbalance

These effects contribute directly to long-term engine reliability.

Procurement and Service Considerations

From a vehicle program or aftermarket supply perspective, ready mix antifreeze coolant simplifies quality control.

Key considerations include:

-

Consistent formulation across supply batches

-

Reduced dependence on local water quality

-

Lower training requirements for service personnel

-

Predictable performance across regions

For organizations managing multiple vehicle platforms, these factors often outweigh the reduced flexibility of fixed concentration.

Q&A

Q: Does ready mix coolant cool engines better than concentrate?

Cooling performance is similar when both are correctly prepared. The advantage lies in consistency, not higher efficiency.

Q: Can ready mix coolant be used for top-ups only?

Yes, it is often used to maintain concentration stability during partial refills.

Q: Is ready mix suitable for all climates?

It must be matched to the intended temperature range, as concentration cannot be adjusted in the field.

Applying Ready Mix Antifreeze Coolant in Automotive Engines

Cooling system reliability in automotive engines depends as much on preparation accuracy as on chemical formulation.

FYeco provides automotive antifreeze solutions, including ready mix formulations designed to deliver stable performance by eliminating dilution variability. Reviewing suitable options within FYeco’s product portfolio helps engineers and buyers determine whether pre-diluted coolant fits their vehicle platforms and service practices.

https://www.fyecosolution.com/products

For passenger cars or fleet vehicles serviced across multiple locations, discussing operating conditions with the FYeco team supports a clear, application-driven coolant selection process.

https://www.fyecosolution.com/contact-us