Propylene Glycol Antifreeze: Safety-Focused Cooling Performance in Automotive Engines

In automotive engine cooling systems, fluid selection is not driven by thermal efficiency alone. As vehicle platforms evolve and regulatory pressure increases, safety, environmental impact, and service handling risk have become part of the decision process.

Propylene glycol antifreeze is therefore specified in certain automotive applications where lower toxicity and reduced environmental risk outweigh marginal differences in heat transfer performance. In real vehicles, however, whether this choice delivers stable cooling over time depends on formulation design and how the coolant interacts with engine materials and driving conditions.

Understanding how this base fluid behaves inside a car engine helps engineers and buyers avoid performance compromises that are often blamed on the coolant rather than on mismatched formulation.

Why Automotive Platforms Specify Propylene Glycol–Based Coolant

The decision to use propylene glycol in automotive engines usually originates from system-level safety requirements, not from a pursuit of higher cooling capacity.

Vehicle manufacturers and fleet operators consider this base fluid when:

-

Cooling systems are serviced frequently in populated environments

-

Regulations emphasize lower toxicity and safer disposal

-

Vehicle platforms operate in markets with stricter environmental rules

-

Exposure risk during leaks, accidents, or maintenance must be minimized

From a materials perspective, propylene glycol provides predictable viscosity behavior across typical automotive temperature ranges and supports modern additive systems. Its safety profile makes it suitable for passenger cars and light commercial vehicles where human interaction is unavoidable.

Formulation Trade-Offs in Automotive Engine Use

Compared with alternative base fluids, propylene glycol introduces specific engineering trade-offs that must be addressed at the formulation level.

In automotive engines, this base fluid:

-

Exhibits higher viscosity at low and moderate temperatures

-

Transfers heat less efficiently under identical conditions

-

Requires tighter control of additive balance to maintain flow efficiency

To compensate, automotive-grade formulations rely on optimized corrosion inhibitors, stronger buffer systems, and effective deposit control additives. These elements ensure that aluminum engine blocks, cylinder heads, and mixed-metal components remain protected without narrowing thermal margins.

When formulation quality is insufficient, drivers may experience gradual temperature rise, reduced heater efficiency, or early coolant degradation—issues often misattributed to the base fluid itself.

How Coolant Chemistry Evolves in Real Driving Conditions

Automotive engines expose coolant chemistry to constant variation.

During city driving, frequent start-stop cycles accelerate thermal stress. On highways, sustained load increases oxidation pressure. Seasonal temperature swings repeatedly shift viscosity and flow behavior. Over time, inhibitors interact with metal surfaces, buffers neutralize acidic by-products, and trace contaminants enter the system through hoses and seals.

In well-balanced formulations, these processes remain controlled. In poorly matched systems, chemical drift accelerates, leading to deposit formation on heat-transfer surfaces or reduced corrosion protection. This gradual evolution explains why extended stability depends on formulation structure rather than initial test results.

Matching Coolant Choice to Automotive Driving Profiles

Selecting propylene glycol antifreeze for automotive engines requires matching formulation behavior to how the vehicle is actually driven.

Passenger Cars (Urban and Mixed Driving)

Safety and environmental considerations are often prioritized. Formulations must manage viscosity effects while maintaining corrosion protection in aluminum-heavy engines.

Fleet and Light Commercial Vehicles

Higher annual mileage and longer operating hours place greater demand on additive stability. Here, inhibitor reserve and buffer strength are more critical than nominal freeze protection.

High-Temperature and Turbocharged Engines

Thermal margins are tighter. Deposit control and consistent heat transfer become essential to avoid localized overheating.

When matched correctly, propylene glycol antifreeze supports safe and predictable cooling performance across these driving profiles.

Performance Comparison in Automotive Engine Cooling Systems

In automotive engines, the difference between propylene glycol–based coolant and conventional alternatives is not limited to toxicity labels. The real distinction appears in fluid dynamics, heat transfer behavior, and long-term chemical stability under engine operating cycles.

| Technical Aspect | Propylene Glycol–Based Coolant | Conventional Alternatives |

|---|---|---|

| Acute toxicity risk | Significantly reduced, safer during leaks or servicing | Higher, stricter handling and disposal requirements |

| Thermal conductivity | Slightly lower, requires optimized flow and additive balance | Higher, more forgiving in marginal cooling systems |

| Dynamic viscosity (operating temp) | Higher, impacts pump load and low-speed circulation | Lower, easier flow at comparable temperatures |

| Deposit sensitivity | More sensitive to formulation quality and inhibitor balance | Generally more tolerant |

| Regulatory compliance margin | Broader acceptance in safety-focused markets | Narrower in restricted regions |

From an automotive engineering perspective, propylene glycol antifreeze shifts part of the performance burden from the base fluid to formulation design and system matching. Platforms that accept this trade-off do so deliberately, prioritizing reduced exposure risk and regulatory flexibility while relying on carefully engineered additive systems to preserve cooling stability.

Procurement and Platform Considerations for Automotive Use

From a vehicle program or fleet procurement perspective, evaluating propylene glycol antifreeze involves more than confirming safety classification.

Key questions include:

-

Is formulation consistency maintained across production batches?

-

Does viscosity behavior align with engine cooling system design?

-

Is compatibility confirmed with seals, hoses, and aluminum alloys?

-

Can technical support address platform-specific operating conditions?

These factors influence long-term reliability more than base fluid choice alone.

Q&A

Q: Does lower toxicity reduce cooling performance in car engines?

Not inherently. Performance depends on formulation balance and system matching.

Q: Is this base fluid suitable for modern aluminum engines?

Yes, when inhibitor systems are designed specifically for automotive materials.

Q: Does safety-focused coolant require more frequent replacement?

Service interval depends on chemical stability and driving conditions, not toxicity level.

Applying Safety-Focused Coolant Solutions in Automotive Engines

Cooling performance in automotive engines is the result of formulation stability matched to real driving behavior.

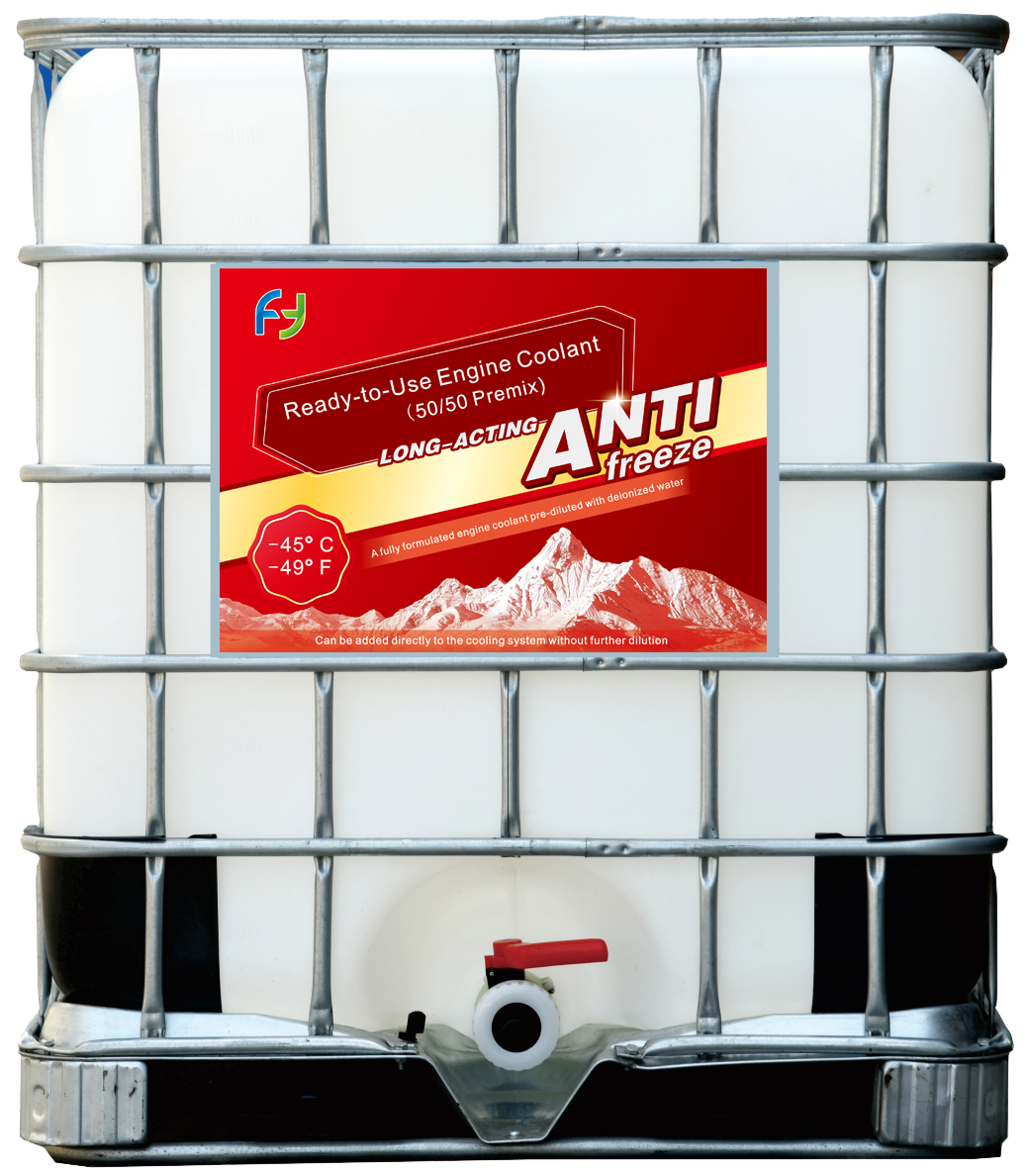

FYeco develops antifreeze and additive solutions designed specifically for automotive engine cooling systems, including formulations based on propylene glycol where safety and regulatory requirements apply. Reviewing suitable options within FYeco’s product portfolio helps engineers and buyers evaluate whether this approach fits their vehicle platforms.

https://www.fyecosolution.com/products

For passenger cars or fleet vehicles operating under diverse driving conditions, discussing platform details with the FYeco team supports a clear, application-driven coolant selection process.

https://www.fyecosolution.com/contact-us