Automotive Antifreeze Manufacturer: Material, Process, and Supply Factors Buyers Actually Evaluate

When procurement teams search for an automotive antifreeze manufacturer, they are rarely looking for a basic product introduction.

They are evaluating risk.

Risk related to formulation stability, batch consistency, long-term supply, and whether the manufacturer can support real operating conditions—not just deliver a liquid that meets an initial specification.

This article focuses on how antifreeze is actually built, controlled, and supplied, and what buyers should verify before approving a manufacturer.

Antifreeze Materials: What Really Determines Performance and Stability

From a material perspective, automotive antifreeze coolant is a multi-component chemical system, not a single raw material.

A typical formulation structure includes:

-

Base fluid

-

Ethylene glycol (EG) or propylene glycol (PG)

-

Determines freeze/boil protection and heat capacity

-

-

Corrosion inhibitor package

-

Protects aluminum, steel, cast iron, copper, and solder

-

Determines long-term engine protection

-

-

Buffer system

-

Controls pH drift under thermal stress

-

Critical for long service intervals

-

-

Functional additives

-

Foam suppression

-

Deposit control

-

Electrical conductivity management (when required)

-

What differentiates one automotive antifreeze manufacturer from another is not the base fluid, but how inhibitor chemistry is selected, balanced, and controlled over time.

Manufacturing Process: Why Batch Control Matters More Than Capacity

Antifreeze production is not simply blending liquids in a tank.

Consistency depends on process discipline.

A qualified automotive antifreeze manufacturer typically controls:

-

Raw material qualification and traceability

-

Controlled blending sequence (additive order matters)

-

Temperature and mixing time during formulation

-

In-process testing before batch release

Without strict process control, inhibitor distribution can vary from batch to batch—even if the formulation sheet remains unchanged.

Typical Manufacturing Control Comparison

| Process Factor | Basic Supplier | Qualified Manufacturer |

|---|---|---|

| Raw material traceability | Limited | Full batch traceability |

| Blending control | Manual / semi-manual | Standardized, monitored |

| In-process testing | Optional | Mandatory |

| Batch-to-batch consistency | Variable | Controlled |

| Long-term formulation lock | No | Yes |

For buyers, this directly affects field performance consistency.

Formulation Structure: One Product vs Application-Driven Design

Many suppliers offer a fixed antifreeze product and expect customers to adapt.

A capable automotive antifreeze manufacturer works the opposite way—adjusting formulation structure based on application.

Typical adjustable parameters include:

-

Inhibitor type and reserve level

-

Buffer strength for high thermal load

-

Compatibility focus for aluminum-heavy engines

-

Conductivity limits for electrically sensitive systems

This formulation flexibility is critical for OEMs, fleet operators, and export projects where operating conditions differ significantly from standard passenger vehicles.

Procurement Reality: How Antifreeze Projects Are Actually Evaluated and Approved

In real procurement scenarios, antifreeze projects are rarely approved based on price lists or specification sheets alone.

What procurement teams evaluate is execution risk.

Typical approval discussions focus on three practical questions:

-

Can the formulation remain consistent across repeated orders?

Procurement teams are often less concerned with the first delivery and more concerned with whether the same antifreeze formulation will be supplied six months or one year later without silent changes. -

How flexible is the manufacturer when operating conditions change?

Engines may be deployed in different regions, climates, or duty cycles after initial approval. Buyers value manufacturers who can adjust antifreeze formulation structure—such as inhibitor balance or buffer strength—without restarting the entire qualification process. -

Is the communication path clear once the order is placed?

Delays and mismatches often occur not during quotation, but during formulation confirmation, packaging coordination, and documentation alignment. Manufacturers with clear technical and commercial coordination reduce internal procurement workload.

For buyers, reducing uncertainty in these areas is often more valuable than optimizing unit cost.

Selecting Engine Antifreeze Coolant Based on Vehicle and Application Type

Engine antifreeze coolant selection should vary by vehicle type and operating profile, not be treated as a universal decision.

Different automotive applications place very different demands on coolant chemistry:

-

Passenger vehicles

Typically operate under moderate thermal load with predictable service intervals. Antifreeze coolant selection focuses on long-term corrosion protection and material compatibility rather than extreme stability margins. -

Commercial vehicles and fleet engines

Often experience extended operating hours and higher load variation. In these cases, engine antifreeze coolant must prioritize inhibitor reserve and thermal stability to avoid accelerated degradation during continuous use. -

Heavy-duty and off-road vehicles

Face higher contamination exposure, uneven cooling conditions, and limited maintenance windows. Coolant formulation must tolerate stress without rapid pH drift or deposit formation. -

Electrified and sensor-dense vehicles

Require attention to coolant conductivity and compatibility with electronic components. Standard antifreeze formulations may introduce risks that are invisible during short-term testing.

By aligning engine antifreeze coolant formulation with vehicle category and real operating behavior, buyers reduce the likelihood of premature maintenance and unexpected system issues.

Common Buyer Risks When Selecting an Antifreeze Manufacturer

From procurement experience, the most common issues include:

-

Inconsistent formulation across batches

-

Silent formulation changes due to raw material substitution

-

Limited technical support after delivery

-

Overpromised service intervals without validation

These risks usually surface after installation, when correction is costly.

Q&A

Q: Can one automotive antifreeze manufacturer support both OEM and aftermarket supply?

A: Yes, if formulation control and production processes ensure consistency across different volumes.

Q: Is private labeling a guarantee of manufacturing capability?

A: No. Private labeling does not reflect formulation ownership or process control.

Q: Should MOQ be the main selection factor?

A: No. MOQ affects procurement flexibility, but formulation stability affects long-term cost.

Working with an Automotive Antifreeze Manufacturer as a Long-Term Partner

Selecting an automotive antifreeze manufacturer should be treated as a system decision, not a spot purchase.

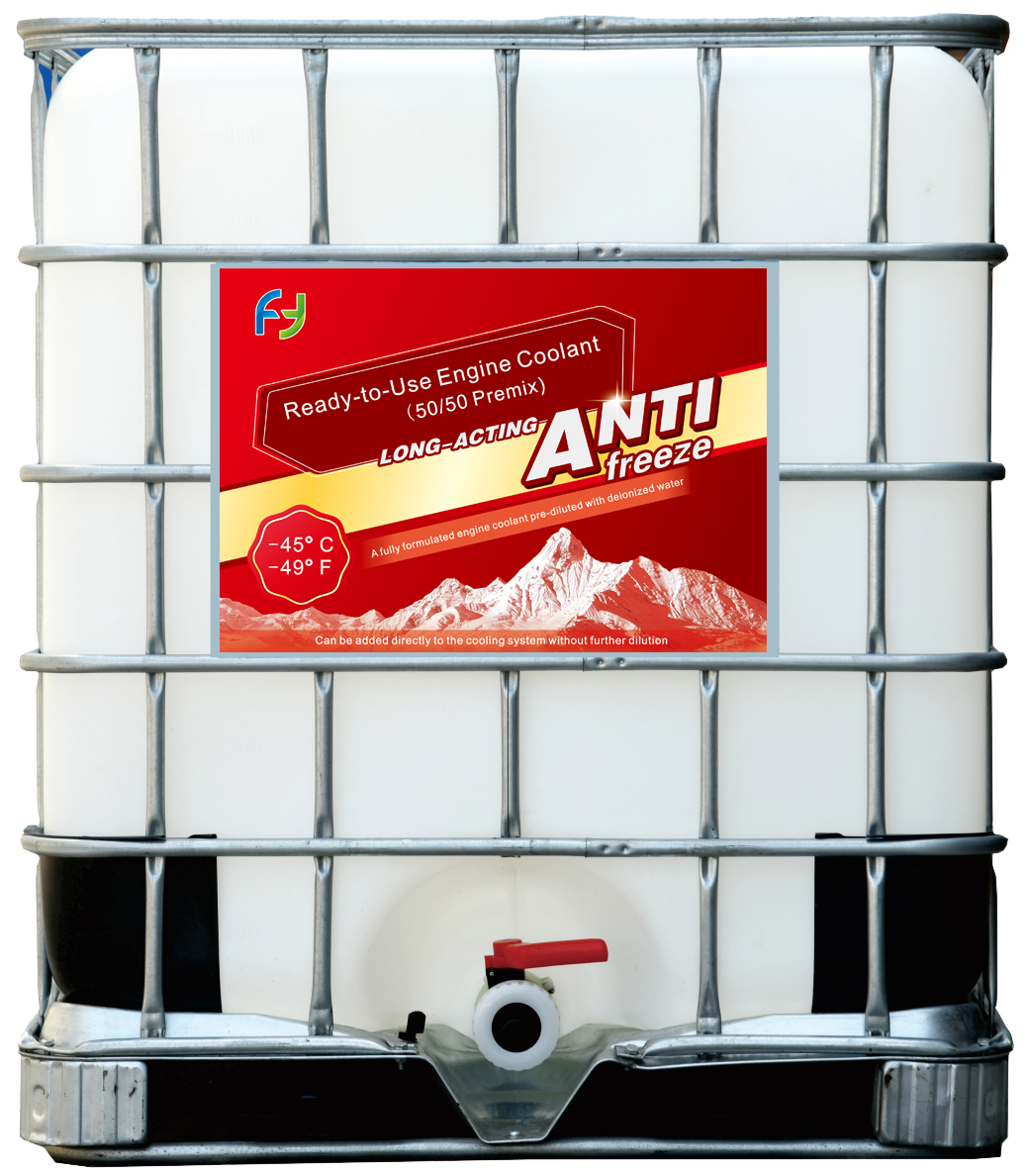

FYeco manufactures antifreeze coolants and additive solutions with controlled formulation processes, application-driven design, and transparent supply parameters. Buyers can review available antifreeze coolant solutions and additive systems through the FYeco product portfolio:

https://www.fyecosolution.com/products

For projects involving custom formulations, specific engine materials, or defined service life targets, discussing requirements directly with the FYeco team allows antifreeze manufacturing and supply decisions to follow a clear, structured process from evaluation to delivery:

https://www.fyecosolution.com/contact-us